|

|

Treatment of glassesWe have made it our aim to constantly further our high standards of glass development and we have concentrated on the development of glass in thicknesses between 3mm and 19mm,which for the most part is used for furniture, interior fitments and all types of architectural projects.The machinery at our disposal enables us, in combination with many manufacturing possibilities and based on our many years of experience, to undertake individual projects of the highest order for private clients just as for commercial projects.Be inspired by our manufacturing potential. Together we will give shape and form to your vision.It is our pleasure to count you amongst our satisfied customers. |

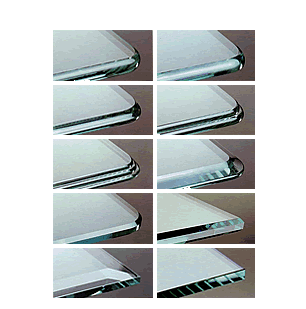

Loops of edgesFloat glass is brilliantly suited to complement almost all types of furniture, interior fitments and interior conversions.The development of glass borders here demonstrates the foundation for an aesthetic and qualitatively valuable product.As wo have a highly modern factory at our disposal, including CNC machinery, countless possibilities are available to us to work in different ways to produce finished.articles and thus to achieve the best possible effects. |

|

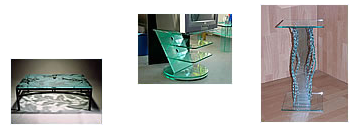

Creation from GlassIdeas from glass in live like also in Decoration |

|

In our gallery we showyou but a small example of the possibilities with glass.Obviously combinations of glasswith other materials such as stone, granite or metal can also be produced.We give your ideas shape and form. |

|

|

|

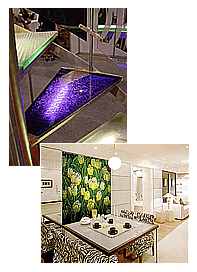

Glass laminateIn the lamination process, special shoots are laid between panes of glass and welded together in special vacuum ovens.Originally, the lamination process was used in solar and safety applications.Through further development of the lamination process, the boundaries of application wore extended repeatedly.Today wo can produce astounding visual effects in glass, which also permit various later modifications such as drilling, planning and bending, etc.In conjunction with light, wo are able to produce unique works of art for interior and exterior use.Allow yourself to bo inspired by the multitude of special possibilities in the area of ddcor and design. |

|

varnishingAs replacement for special mochanical surface processing such as corrosion or sandblastHEAD CO.,LTDoffers high-quality and resistant solutions on, the one effect perfectly imitate.In color or transparency.With glass lacquers worked on surfaces are steadier against chemicals and demand.In addition become, differently than with unlacqucrcd glass surfaces, annoying finger marks avoided.The colouring of glass surfaces or bottle glass with glass lacquers represents a more economic alternative to colored glass.The employment of our glass lacquers is particularly popular in the furniture internal area, in the cosmetic-wrapping-industry and within the range household and decoration.special effects arc obtained by this kind of the glass treatment! |

|